Advantages of Laser Label Cutter

Best Entry-level Model with Excellent Cutting Performance

◉ Flexible and fast label laser cutting technology helps your products quickly respond to market needs

◉ Mark pen makes the labor-saving process and efficient cutting & marking operations possible

◉ Upgraded cutting stability and safety - improved by adding the vacuum suction function

◉ Automatic feeding allows unattended operation which saves your labor cost, lower rejection rate (optional auto-feeder)

◉ Advanced mechanical structure allows laser options and customized working table

Delivery date: 45 Days

- Description

- Reviews (0)

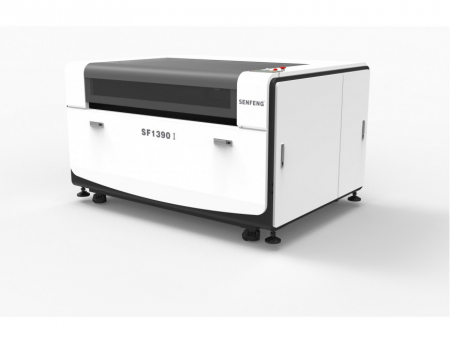

Best Laser Cutter for Small Business

As a small laser cutting machine, the Contour Laser Cutter 90(CCD laser cutter) is widely used to cut the label, patch, sticker, embroidery, and other garment accessories due to the convenience and flexibility in operation. Equipped with a CCD Camera, the label laser cutter can accurately recognize and position the pattern, cut along the outline with high precision and quality. High-resolution and top cutting precision help with different patterns cutting on varied materials.

Technical Data

| Working Area (W*L) | 900mm * 500mm (35.4” * 19.6”) |

| Software | CCD Software |

| Laser Power | 50W/80W/100W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Drive & Belt Control |

| Working Table | Honey Comb Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

How does CCD Camera work on Laser Cutting Machine?

1. Image Capture:

The CCD camera captures images of the material or work surface. The images may contain printed patterns, embroidery designs, or colorful elements.

2. Pattern Recognition:

The CCD processes the captured images and uses pattern recognition algorithms to identify specific designs or patterns. It breaks down the images into pixels and analyzes the color and shape of each pixel.

3. Data Processing:

The information gathered from the pattern recognition is processed by a computer system associated with the laser cutter. The computer translates the recognized patterns into cutting instructions for the laser.

4. Laser Cutting:

The laser cutter receives the instructions from the CCD system. It then uses a high-powered laser to cut or engrave the material precisely based on the identified patterns.

5. Precision Control:

The CCD system continuously monitors the material's position and adjusts the cutting path in real-time. This ensures precise alignment and accurate cutting according to the identified patterns.

![Contour Laser Cutter 90 [0] Contour Laser Cutter 90 [0]](https://gomagcdn.ro/domains2/allstitch.ro/files/product/medium/masina-de-taiat-cu-laser-de-pe-contur-cu-camera-ccd-all-90-contur-691928.webp)

![Contour Laser Cutter 90 [1] Contour Laser Cutter 90 [1]](https://gomagcdn.ro/domains2/allstitch.ro/files/product/medium/masina-de-taiat-cu-laser-de-pe-contur-cu-camera-ccd-all-90-contur-376574.webp)

![Contour Laser Cutter 90 [1] Contour Laser Cutter 90 [1]](https://gomagcdn.ro/domains2/allstitch.ro/files/product/large/masina-de-taiat-cu-laser-de-pe-contur-cu-camera-ccd-all-90-contur-691928.webp)

![Contour Laser Cutter 90 [2] Contour Laser Cutter 90 [2]](https://gomagcdn.ro/domains2/allstitch.ro/files/product/large/masina-de-taiat-cu-laser-de-pe-contur-cu-camera-ccd-all-90-contur-376574.webp)